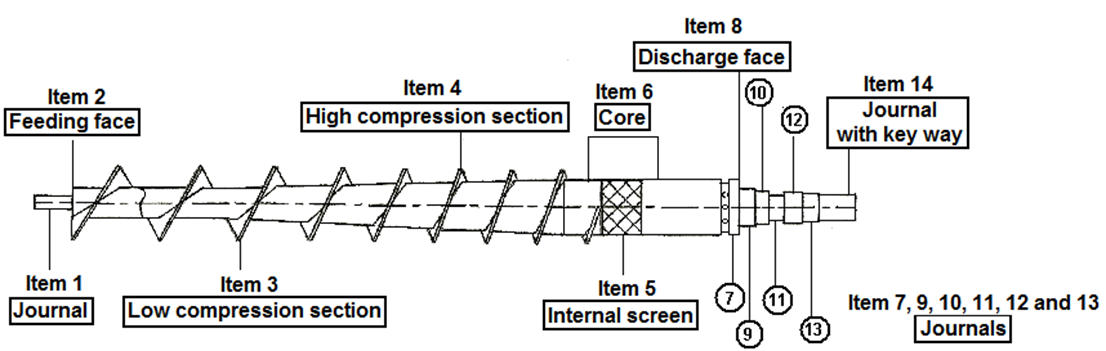

Screw Shaft

Why are we the screw specialists?

After more than 30 years and 800 screws manufactured and rebuilt, we have acquired an expertise which ranks us among leaders in the industry.

The choices of our hard facing coatings

The traditional

Chromium carbide having a high chromium concentration specially formulated for us and which has proven its efficiency over the years.

The Tungsten carbides

- type 1 with 12% concentration

- type 2 with 55% concentration

- type 3 with 65% concentration

For every type of coating we apply a specific thickness in order to obtain the maximum carbide concentration and minimum cracking.

Surface treatment

Application of a high abrasive resistant ceramic (we are one among few in Quebec to be certified by the manufacturer)

The ceramics overlay process will increase your consistency by 10% to 15%. It is not expensive and it will protect your screw against wear due to abrasion. We have been using it since 2003 and have witnessed the effectiveness of this process.

Configuration of bodies and flights

- For every screw we inspect, we correct, if needed, the run out and attrition in order to balance the flow- through.

- We give each flight a positive thrust to improve efficiency and useful life.

Optimization of the screw

Regular double flights

Mixer type double flights

Prevention

No matter what is done, manufacturing or rebuilding, every screw is subject to a meticulous exam where every square centimeter is visually inspected and a dye penetrating test is performed to detect any sign of potential cracking.

Service

We have the expertise to dismantle and to reassemble your complete press. Furthermore, we do have in stock a wide variety of spare parts.

Additional Services

- X-Ray

- Sand blast

- Stress release